The manufacturing process and advantages of aluminum alloy curtain rods

Date: 2021-12-06 Categories: Industry News Hits: 1569 From: Guangzhou Jiejia Decoration Materials Co., Ltd.

Today, Jiejia takes aluminum alloy curtain rods as an example to interpret the manufacturing process and advantages of aluminum alloy curtain rods, for everyone as a reference for choosing curtain rod materials.

Aluminum alloy curtain rods are generally aluminum alloy profiles, and the production of aluminum alloy profiles includes three processes: casting, extrusion and oxidation.

First of all, melting casting is the first process of aluminum production. It calculates the content of various metal components required according to the required aluminum alloy grades, and then reasonably mixes various trace elements. This process is particularly important and directly affects aluminum alloy curtains. The physical and chemical properties of the rod.

Then there is smelting. The prepared raw materials are added to the smelting furnace for smelting according to the process requirements, and impurities and gases are removed through various refining methods. The refined aluminum liquid is cast into various specifications of aluminum casting rods according to the casting requirements.

In the second step of forming, the heated aluminum cast rod is extruded from the mold through a forming extruder according to certain technological conditions. The shape can be designed according to customer needs. There is also an air-cooling quenching process and the subsequent artificial aging process in the extrusion molding to complete the heat treatment strengthening. This process is to ensure that the thickness of the profile is uniform so that the quality can reach a good state.

The third step of oxidation is just a process of aluminum alloy surface treatment, as well as spraying, wood grain transfer, electrophoresis, porcelain bathing, and other processes. The surface of the newly produced aluminum alloy profile is not strong against oxidation and corrosion. It is necessary to perform the surface treatment by anodic oxidation to form a layer of film to enhance the corrosion resistance, wear resistance, and surface aesthetics of the aluminum material. According to the characteristics of aluminum, it can be surface treated into brown, bronze, stainless steel, etc.

In short, the editor believes that aluminum alloy curtain rods are widely used in the market. Due to the large bending characteristics of aluminum, try to choose a standard rod with a uniform wall thickness between 1.0mm and 1.3mm when selecting, and the aluminum alloy has a high-quality surface. The processing characteristics are matched with a variety of color curtains and decoration styles.

Ebay Hot sale curtain accessories rods curtain finials with iron tube adjustable curtain rod sets

Ebay Hot sale curtain accessories rods curtain finials with iron tube adjustable curtain rod sets  China Manufacture Durable Home Extendable Curtain Rod

China Manufacture Durable Home Extendable Curtain Rod  STARDECO FBA Ebay Amazon Top Sale Curtain Rod adjustable pole circular curtain rod

STARDECO FBA Ebay Amazon Top Sale Curtain Rod adjustable pole circular curtain rod  Household white aluminum curtain track curtain with curtain accessories

Household white aluminum curtain track curtain with curtain accessories  High quality factory customized aluminum alloy curtain track production factory household curtain track accessories

High quality factory customized aluminum alloy curtain track production factory household curtain track accessories  STARDECO elegant sun shading roller zebra blinds shades fabric motor control window auto blinds

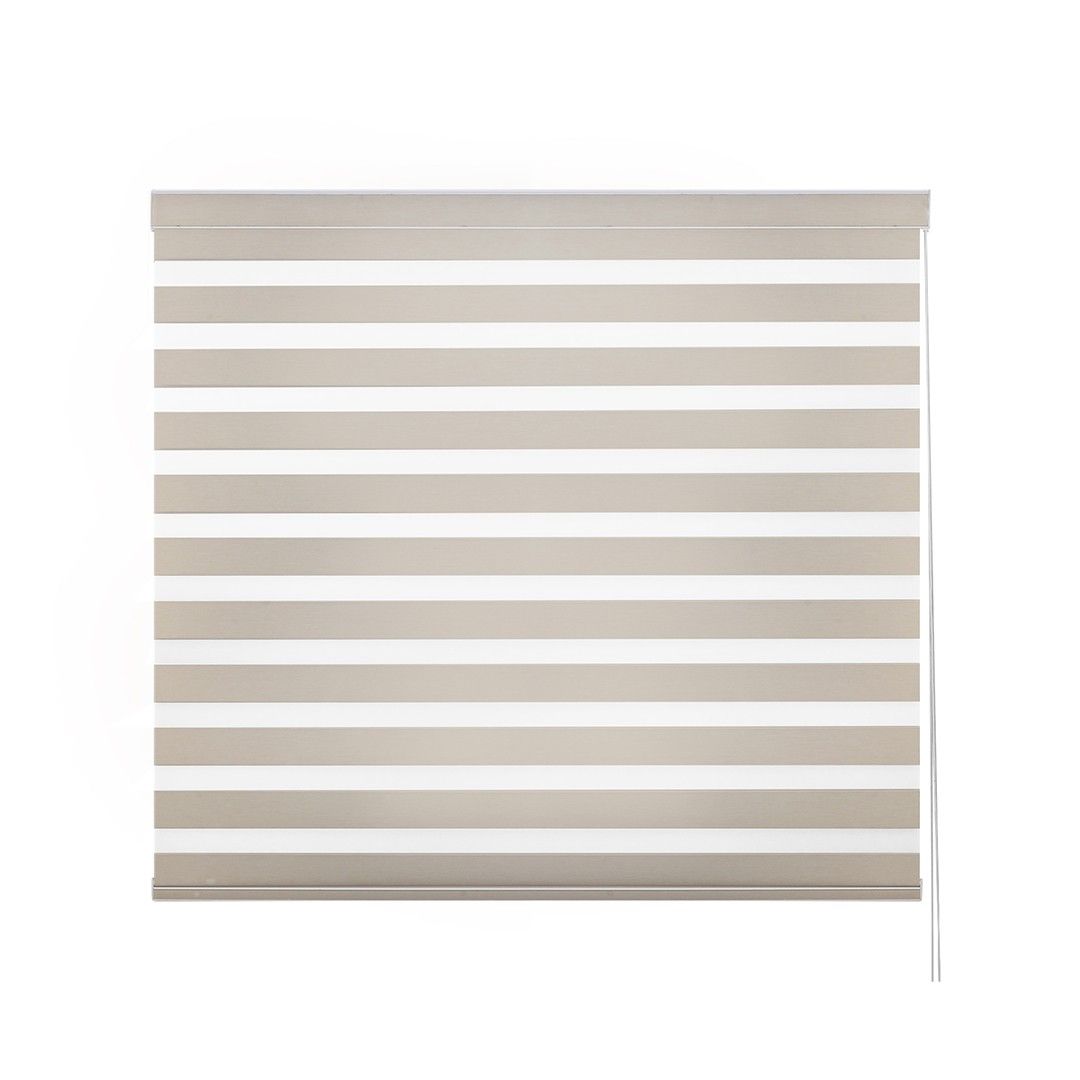

STARDECO elegant sun shading roller zebra blinds shades fabric motor control window auto blinds  New shading and dimming household zebra blinds shutter manual zebra shutter

New shading and dimming household zebra blinds shutter manual zebra shutter  Wholesale factory price modern zebra blinds Curtain simple style indoor office water ripple shading zebra blinds

Wholesale factory price modern zebra blinds Curtain simple style indoor office water ripple shading zebra blinds  BL20 Exquisite imitation hemp sunshade household zebra curtain environmental protection material

BL20 Exquisite imitation hemp sunshade household zebra curtain environmental protection material  BL2 New exquisite sun shading environmental protection household zebra blinds

BL2 New exquisite sun shading environmental protection household zebra blinds